Factory Outline

Everything is manufacturing with high quality.

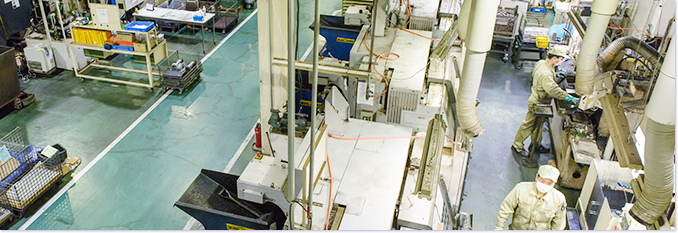

In order to take full advantage of the highest level of processing technology, it is necessary to have the best machines and an environment that makes it ideal. A secure spacious factory's layout has a total area of 4,905 square meters on a site area of 9,203 square meters. By placing machines suited for production of many parts in small quantities using high levels of production efficiency is conducted by constructing a basic manufacturing process. This amount of space is ideal giving the environment provides the ability to produce the highest quality of products prepared or developed at a high rate.

Each person performs multiple steps and maintains a sense high quality proficiency

At the 1st factory, each of our production staff is responsible for operating several machines with multiple steps. As a result, the accuracy of high quality parts is developed. Quality awareness and a sense of responsibility also lead to good results.

We have our own automatic line by the state-of-the-art machines to improve Q-C-D.

We constructed our own assembly line in combination with three high-speed, high-precision and high-rigidity manufacturing center such as the a81 MMC (FMS) and the automated system. With that, we succeeded in drastically reducing manufacturing time and further improved production accuracy as well as lightening the burden of working staff that jobs consist of detaching and reattaching parts.

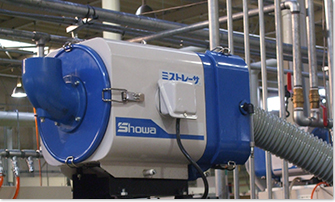

Environment-friendly and clean working environment

The coolant system makes it possible to recycle the cut pieces of metal that is generated from machines (impurity removal) cutting dry metals or melting them. Therefore, we make the recycled pieces of metal into processing oil. In addition, we produce a mist collector in our machines to assure work with an eco-friendly and clean environment.

Main machine device

Machining Center

This machine has a function to exchange tools automatically by moving the blade back and front, left and right, and up and down by numerical controls and is able to conduct operations (mainly cutting) according to the purpose of the machine such as milling, hollowing and drilling.

The machines are divided and operated in two categories know as "vertical machines" and "horizontal machines". The vertical machines are place in a vertical position, whereas the horizontal machines are place in a horizontal position. By this method, both machines are able to cut metals and materials on a table with a rotating knife.

NC lathe

This machine's function is to control the cutter stand, the distance it travels and the amount of speed it can reach by installing a numerical controller on the lathe of each machine's lathe.

Honing

This machine performs honing by attaching several grindstones to the outer periphery, using a tool between the grinding wheel and the manufactured item in a two-dimensional movement. Normally, this machine is use for mirror finishes and for gutting a hole into a cylinder rod(the inner surface of the cylinder).

Our company produces an inner diameter of 8 DIA ~ 25 DIA and length 250 ~ 300m / m in 10μ units.